|

|

In a world where sustainability is more than just a buzzword, the clothes we wear and the fabrics they are made from matter. One such fabric that has been part of our wardrobes for over a century is rayon — a versatile textile with an intriguing history and complex environmental impacts. As consumers, understanding the nature of this material can help us make informed decisions about our purchases.

Rayon, often touted as a semi-synthetic fabric, is derived from cellulose, a natural component found in wood pulp. With its silk-like texture and impressive durability, it has been widely used in fashion. Nevertheless, the production process of rayon, particularly its environmental implications, has led to debates on whether it can be considered truly sustainable.

In this article, we delve deep into the world of rayon fabric. We explore its origins, characteristics, and manufacturing process. We also shed light on the highly controversial question — Is rayon sustainable?

So whether you’re eager to become a more conscious consumer or just have an interest in textiles, read on to learn more about rayon.

Key Takeaways

- Rayon, a semi-synthetic fabric, mimics natural fibers like silk and cotton but requires a complex, chemical-intensive production process.

- Rayon’s production can contribute to air and water pollution and cause deforestation.

- Despite its natural origins, rayon’s biodegradability is hampered by residual chemicals in landfill conditions.

- Rayon is appreciated for its versatility, comfort, drapability, vibrant color retention, and affordability.

- Compared to cotton, rayon is less durable, requires more careful handling, and has a greater environmental impact.

Short History of Rayon

Rayon’s history dates back to the late 19th century when industrialists sought a cheaper alternative to silk.

Frenchman George Audemars first patented artificial silk in 1855, but it was Sir Joseph Swan who brought the concept to fruition in the 1880s. Initially used for light bulbs, Swan’s cellulose-based fabric was later developed into what is now known as rayon.

Rayon’s commercial production began in earnest in the early 20th century, with its versatility and affordability quickly making it a popular choice among manufacturers and consumers alike.

The fabric has since undergone various modifications and innovations. Different types of rayon, such as viscose, modal, and lyocell, have been introduced over the years. Each type comes with its distinct properties, expanding rayon’s usability across industries, from fashion to medical applications.

What Exactly is Rayon?

Rayon is a semi-synthetic textile made from regenerated cellulose fiber. It’s derived from natural sources, predominantly wood pulp, and agricultural products. Despite its natural origins, rayon undergoes extensive chemical processing to transform it into a wearable material. This process gives it unique characteristics that set it apart from both natural and fully synthetic fabrics.

Unlike synthetic textiles such as polyester or nylon, which are made from petroleum, rayon retains some characteristics of its natural source material. Its fibers can mimic those of cotton, wool, silk, or linen, making it incredibly versatile. However, unlike these more resilient synthetic counterparts, rayon tends to be less durable and requires careful handling, particularly when being washed or dried.

Image source. Viscose rayon fiber.

The Manufacturing Process of Rayon

Manufacturing rayon involves a complex series of chemical reactions. The journey begins with cellulose, usually sourced from wood pulp. This cellulose is purified and then dissolved in a solution of caustic soda. This mixture is left to age in metal containers for a few days.

Next, carbon disulfide is introduced to the mix, creating a yellowish solution known as xanthate. The xanthate is then forced through tiny holes known as spinnerets. As the xanthate exits the spinnerets, it lands in a bath of sulfuric acid, which causes it to solidify into fibers.

Once solidified, these fibers are spun into threads or yarns. At this point, the rayon can be further treated or dyed depending on its intended use. The entire process is labor-intensive and involves the use of various hazardous chemicals, which has raised concerns about its environmental impact and the safety of factory workers.

The Environmental Impact of Rayon Production

The environmental footprint of rayon production is significant and often a point of concern for sustainability advocates.

While the raw material for rayon, cellulose, is renewable, turning it into fabric involves many chemicals, such as carbon disulfide, caustic soda, and sulfuric acid. These chemicals are not only hazardous to the environment but also pose severe health risks to workers if not properly managed.

A prominent issue in rayon production is air and water pollution. The chemical-laden wastewater, if not treated effectively, can be discharged into local water bodies, leading to severe consequences for aquatic life and downstream ecosystems. Air pollution is another challenge since the manufacturing process emits volatile organic compounds contributing to poor air quality.

Furthermore, while rayon is derived from wood pulp, which in theory could be sustainably sourced, the reality is often different. In some cases, natural forests are cleared to make way for pulpwood plantations, contributing to deforestation and loss of biodiversity. Also, the end product — rayon fabric — although biodegradable under ideal conditions, does not degrade as readily in normal landfill conditions due to the residual chemicals present.

Benefits of Rayon Fabric

Despite its downsides, rayon fabric boasts several benefits that make it a popular choice in the textile industry, particularly for clothing.

- Versatility. One of the most significant advantages of rayon is its versatility. It can mimic the qualities of various natural fibers such as silk, cotton, linen, and wool, which makes it adaptable to different styles and uses. From flowing dresses to comfortable shirts, rayon fits a broad spectrum of fashion needs.

- Comfort. Rayon is renowned for its comfort. The fabric is lightweight, breathable, and has a silky texture that feels soft against the skin. This makes it an excellent choice for warmer climates or summer clothing.

- Drapability. Rayon drapes beautifully. Its fluidity and ability to conform to the body’s shape make it a favorite fabric for flowy dresses, skirts, and blouses.

- Vibrant colors. Rayon holds dye well, allowing for vibrant and long-lasting colors. This feature opens up a world of design possibilities for fashion designers and is appealing to consumers who value bold, vivid hues in their wardrobes.

- Affordability. Compared to natural fibers like silk and wool, rayon offers similar aesthetic appeal and comfort at a lower price point, making fashionable clothing more accessible to a wider audience.

Rayon Fabric vs. Cotton

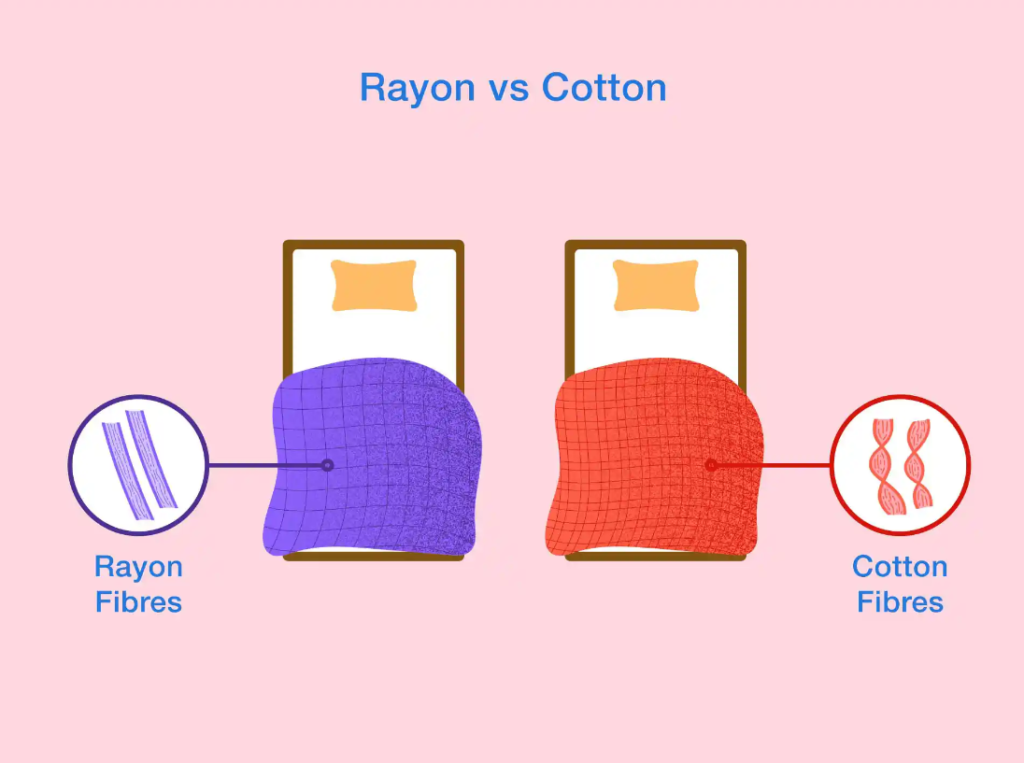

When comparing rayon and cotton, some distinct differences and similarities come to light. Both are used extensively in the textile industry, but they each have unique properties that influence their usage.

- Origin. Cotton is a completely natural fiber harvested from the cotton plant. Rayon, on the other hand, is a semi-synthetic fabric made from regenerated cellulose, usually sourced from wood pulp.

- Durability. Cotton generally has superior durability compared to rayon. It can withstand high temperatures and various washing methods and tends to be more resistant to wear and tear. Rayon, although relatively durable, weakens when wet and requires more careful handling and washing.

- Feel & appearance. Both fabrics can be incredibly soft and comfortable. Rayon often mimics the smooth, luxurious texture of silk, making it drape well and giving it a shiny appearance. Cotton, while also soft, has a more matte finish and can vary in texture depending on its weave.

- Breathability. Both rayon and cotton are breathable fabrics making them suitable for warm climates or summer clothing. However, cotton tends to be more absorbent than rayon, making it better at wicking away moisture.

- Environmental impact. The environmental impact of both fabrics varies considerably. Cotton farming can be water-intensive and often involves the use of pesticides unless it’s organically grown. Rayon production involves chemically intensive processes that can be harmful to the environment if not managed correctly.

Final Thoughts

Rayon, a semi-synthetic fabric, has proven itself to be versatile and affordable, lending itself well to the textile industry. However, its production process raises significant environmental concerns, from hazardous chemical usage to deforestation for pulpwood. Despite its advantages, such as comfort, adaptability, and vibrant color retention, rayon’s sustainability remains questionable.

It is crucial for consumers to be conscious of this when considering their fashion choices. Efforts should be encouraged within the industry to mitigate rayon’s environmental impact, making it a more truly sustainable fabric option for the future.