|

|

Every day, consumers around the world put on garments made from elastane or spandex, enjoying the comfortable stretch and fit these materials provide. Yet, few of us stop to consider the origins of these fabrics or think about their impacts on our environment.

Elastane and spandex are terms often used interchangeably in the textile industry. Despite their common usage, there is a subtle distinction between them that many don’t notice. Both materials offer exceptional elasticity, but their production processes and environmental footprints differ significantly.

These differences can play a crucial role in steering the course toward sustainability in the fashion industry.

This article aims to shed light on these two widely used materials — elastane and spandex. Below, we delve into their origins, production processes, characteristics, and potential environmental impacts. So, if you’re ready to make more informed choices about your wardrobe that align with sustainable practices, or you’re simply looking to expand your knowledge about textiles, read on to learn more.

Key Takeaways

- Elastane and spandex are synthetic fibers known for elasticity.

- Their manufacturing process is complex, petroleum-based, energy-intensive, and involves significant use of chemicals.

- Elastane and spandex’s environmental impacts range from high resource consumption to non-biodegradability and microplastic pollution.

- Fabrics like organic cotton blends, Tencel™ Lyocell, recycled materials, and biodegradable synthetics offer more sustainable alternatives.

- Transitioning to sustainable fashion requires collective efforts, including supporting ethical brands and making informed, environmentally-friendly choices.

What Are Elastane and Spandex?

Elastane and spandex are both synthetic fibers renowned for their exceptional elasticity, which is why they’re popular choices in the production of clothing items that require a high degree of flexibility. These materials can stretch up to five times their original length without breaking, and when released, they quickly return to their original shape.

The term “spandex” is an anagram of the word “expands,” which highlights its key property. In contrast, “elastane” is a term derived from “elastic urethane,” pointing towards its chemical makeup. Despite the different names, elastane and spandex are virtually identical in composition and functionality.

Both these materials have fundamentally changed the fashion industry since they were first introduced in the late 1950s. They offer a comfortable fit and flexibility that cotton and other natural fibers simply cannot match on their own. This is why you’ll often find elastane or spandex in anything from sportswear and swimwear to gloves and hosiery.

How Are They Made?

Both elastane and spandex are made through a complex, multi-step chemical process that begins with raw materials, primarily petroleum-based products.

Whether you call it elastane or spandex, both fabrics are created by polymerizing a mixture of macroglycol and a diisocyanate. After the prepolymer process, the resulting solution is reacted with a diamine, which extends the polymer chain, creating polyurethane. The solution is then pushed through a spinneret to create fibers, which are treated to set their properties.

While the exact process may differ slightly depending on the manufacturer or specific end-use of the material, they all involve complex chemistry and precise control over the reaction conditions to produce the highly stretchable fibers we know as elastane or spandex.

Key Characteristics of Elastane and Spandex

Elastane and spandex have several key characteristics that make them highly sought after in the textile industry.

- Exceptional elasticity. Both materials can stretch up to five times their original length without breaking. This elasticity is not only advantageous for comfort and fit but also enhances the durability of garments made from these materials.

- Resilience. These fabrics are resilient and recover quickly to their original shape after being stretched, ensuring the garment maintains its fit over time.

- Lightweight. Despite their strength and durability, elastane and spandex are lightweight, adding minimal bulk to garments.

- Versatility. Elastane and spandex blend well with other fibers. This means they can be combined with natural or synthetic fibers to enhance elasticity in a wide range of garments, from denim jeans to fitted dresses.

- Smooth and soft texture. Garments made from these materials offer a smooth and soft texture, providing a comfortable feel against the skin.

- Breathability. While not as breathable as some natural fibers like cotton, elastane, and spandex still offer a degree of breathability, which can be enhanced when blended with other fibers.

Environmental Impacts of Elastane and Spandex Production

The production of elastane and spandex, like many synthetic fibers, has significant environmental implications.

- Resource consumption. Both elastane and spandex are derived from petroleum, a non-renewable resource. The extraction and processing of petroleum have substantial environmental impacts, including habitat destruction, water pollution, and greenhouse gas emissions.

- Energy intensive. The production process for these materials is energy-intensive, further contributing to carbon emissions.

- Non-biodegradable. As synthetic materials, elastane and spandex are not biodegradable. They can persist in the environment for hundreds of years after being discarded, contributing to the growing problem of textile waste.

- Microplastic pollution. During washing, garments made from these materials can shed microfibers — tiny pieces of plastic less than 5 mm in length. These microfibers can end up in our oceans, posing a threat to marine life and entering the food chain.

- Chemical usage. The manufacturing process involves an array of chemicals, some of which can be harmful to the environment if not managed properly. These include solvents used in spinning the fibers and dyes used in coloring the fabric.

While these impacts present significant challenges, advancements in technology and growing awareness about sustainability are leading to innovations aimed at reducing the environmental footprint of these and other synthetic materials.

Eco-Friendly Alternatives to Elastane and Spandex

As awareness of the environmental impact of synthetic materials like elastane and spandex grows, a number of more sustainable alternatives are being explored.

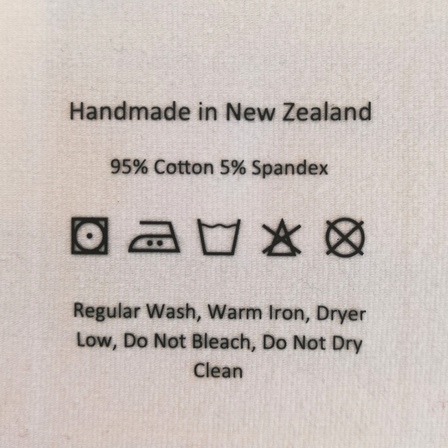

- Organic cotton and spandex blend. While still containing a small percentage of spandex for stretch, using organic cotton significantly reduces the environmental impact. Organic cotton is grown without harmful chemicals and requires less water than conventional cotton.

- Tencel™ Lyocell. This is a type of rayon that comes from sustainably sourced wood pulp. It’s produced in a closed-loop system where 99% of the chemicals and solvents used in the process are recovered and recycled.

- Recycled materials. Fabrics made from recycled materials, such as recycled polyester or nylon, can provide similar properties to elastane and spandex with less environmental impact.

- Biodegradable synthetics. Innovations in textile technology have led to the development of biodegradable synthetic fabrics that break down much faster than traditional synthetics.

While these alternatives offer promising solutions, each has its own set of challenges to overcome, including cost, scalability, and performance characteristics. However, with ongoing research and development, they represent important steps toward a more sustainable fashion industry.

How to Choose the Right Spandex/Elastane Content?

Different fabrics can contain a diverse range of spandex content. If you’re uncertain about the ideal spandex percentage for your fabric-related project, here’s a simplified guide to assist you:

- A content of 3-5% enhances comfort for tight-fitting clothes, such as fitted t-shirts made of cotton/elastane single jersey or skinny jeans crafted from stretch denim.

- A higher concentration, around 10-12%, ensures better shape retention (preventing issues like saggy knees) for highly fitted items like leggings and certain activewear.

- Lastly, 20% or more is most suitable for high-performance athletic and swimwear.

Final Thoughts

The journey toward a more sustainable fashion industry is a shared responsibility. While elastane and spandex have revolutionized the industry with their incomparable stretch and fit, it’s crucial to acknowledge and address their environmental impacts.

The advent of eco-friendly alternatives to these synthetic fibers is a promising step in the right direction. However, it’s equally important for us, as conscious consumers, to make informed choices that favor sustainability. By supporting brands that prioritize ethical practices and making smart decisions about our own wardrobes, we can collectively steer the fashion industry toward a more sustainable future.

After all, fashion doesn’t have to be a choice between style and sustainability. With the right materials and mindful practices, we can enjoy the best of both worlds. Through continued innovation, education, and mindful consumption, we can all play a part in shaping a greener, more sustainable fashion industry.