|

|

Co-authored by Jared Wolf

Biking is a common activity for billions of people. It gets you outside, provides exercise, and can be a convenient mode of transportation for local travelers. For city commuters, biking is also an excellent way to reduce carbon footprints. However, with this friendly pastime comes an industry in serious need of improvement. Let’s take a closer look at the sustainability of bike manufacturing.

Busy? Try the speed.

The scoop: Biking connects billions of people from around the world. It can be a great tool to reduce personal carbon footprints too. But not all bike companies focus on ethics and sustainability.

The manufacturing problem: Since the 2000s, most bikes are manufactured in Asia, where workers’ rights are less transparent. It is difficult to track worker conditions in these parts of the world.

Steel requires energy: Metal itself can be sustainable, but certain forms of steel require lots of energy to extrapolate. It is important to look for sustainably-sourced steel.

Read below for a full list of ethical bike manufacturers.

Dig deeper → 4 min

Producers struggling to keep up with demand

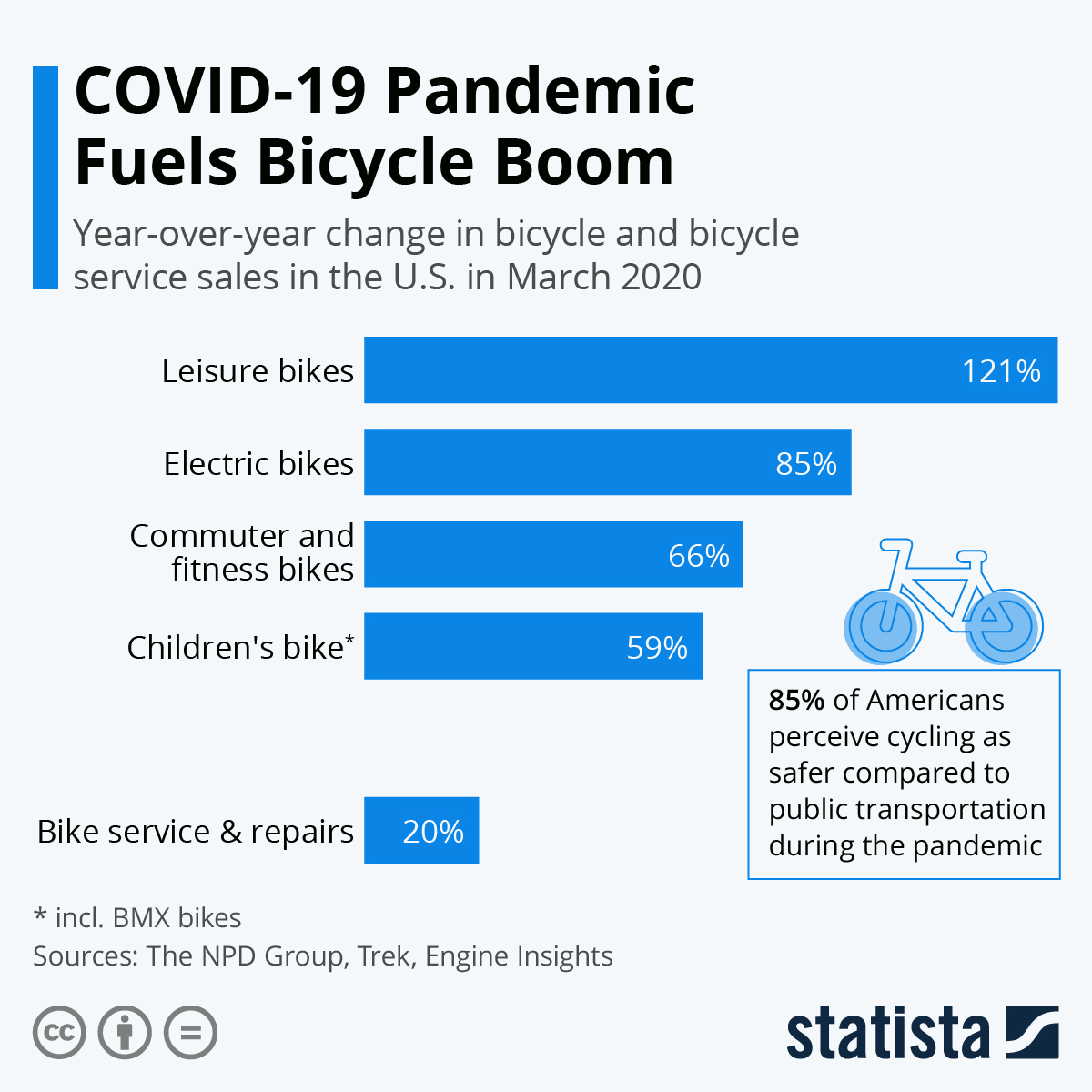

Last year, a major “bike boom” emerged in response to the pandemic. Why? Perhaps it was due to concerns about public transportation. Maybe people were looking for alternative modes of exercise when gyms around the country shuttered their doors. Most of all, I think work-at-home parents realized they had extra time with the kids, and they needed a new family activity.

See also: ‘Plogging’ will change the way you exercise.

Whatever the reason, bike manufacturers saw a massive increase in demand. The air got cleaner, streets got quieter, and millions took on biking.

With this unexpected surge in popularity, bike manufacturers struggled to keep up with demand. In many factories, production capacities decreased. Suddenly, bicycle retailers became an essential service—treated in the likes of liquor and grocery stores.

Imagine you are in a boardroom in December 2019, planning for the next fiscal year. You project 1,000 bikes per distributor each month. March comes along, and suddenly your client is asking for 10,000 bikes. Steel takes time to produce. How can you keep up?

The rise of outsourced materials

The majority of American bicycles use imported steel from Southeast asia. So when demand spiked in March and April 2020, bicycle supply chains suffered. By the summer, COVID-19 restrictions shook enough factories that a considerable bike shortage emerged.

“Although U.S.-based manufacturers like Trek, Specialized or Redline are popular bike brands in the United States, the majority of products are manufactured abroad: Around 99 percent of bicycles sold in the United States are imported from China and Taiwan.” – I. Wagner, Statista (September 2019).

Personally, I ride a Cannondale manufactured in the early 2000’s. I went to a bike shop to get a summer repair. The shop owner pointed out my “made in USA” label with a red, white, and blue flag plastered on the frame.

“We don’t see a lot of these anymore”, he said.

The problem with bike manufacturing

There is no doubt that bicycles share a growing multi-billion-dollar industry. That may sound like a great pathway for sustainability. More bikers = less cars = fewer carbon emissions. Right? Well, like most things in life, there are pros and cons. Here’s how bike manufacturing chalks up for sustainability.

It may come as a surprise that the bicycle and bicycle component manufacturing industry is not very sustainable… or ethical.

Many cycling brands focus on profits in place of sustainable manufacturing. Sustainable alternatives exist, but they require slower processes. Some bikes are handmade by skilled craftsmen rather than factory workers operating heavy machinery. That allows for safer worker conditions and more carefully sourced materials.

Because most bicycles and cycling components are now manufactured in Asia, there is very little transparency around its supply chain.

Is my bike sustainably sourced? Does it follow proper manufacturing standards? Does the bike manufacturer use recycled materials? Do they minimize the waste of materials? How do they dispose of their waste?

As a consumer, it is almost impossible to find an answer to these questions. Most bicycle brands that outsource their materials do not share information about their suppliers.

How bike manufacturers can improve sustainability

Big bicycle brands do very little to standardize outsourcing. Pressuring third-party suppliers to enact better worker conditions and consider sustainably-sourced materials would be a good place to start.

Our goal is to challenge bike companies to hold greater standards for suppliers by partnering with ethics-driven certifications and coalitions.

If more bike-related companies challenge the current manufacturing process, we will eventually see more sustainable production lines.

What you can do to improve the sustainability of bike manufacturing

We recommend purchasing from bike manufacturing companies that are driven by sustainability and ethics. Here is a list of sustainable bicycle brands:

- Brooklyn Bicycle Co. – made in USA, using sustainable steel and vegan leather

- Booomers – ethically made in Ghana, made from bamboo. Safe worker conditions, sales support local initiatives.

- Detroit Bikes – made in USA, American-sourced steel, largest US bike manufacturer.

- Pashley Bikes – made in UK by skilled craftsmen, using sustainable steel frames (ships internationally)

Future generations will thank you. Take action to improve sustainability in the cycling industry by more carefully choosing what to ride. Use your voice as a consumer to make a difference. #BikeEthically

No Comments